This post is a guide on lean visual management. What this is, and why should you care? In a nutshell, visual management in the context of lean manufacturing is a strategy used to foster collaboration, communication, and efficiency inside an organization through the use of visual aids and tools.

So, that’s what this post is about: explaining what visual management is in more detail, its main benefits, and how it works.

We’ll start with a brief introduction to the overall topic, in which you’ll be treated to a brief history of the lean system. Then, you’ll get an overview of the lean system, including its workings and main benefits.

Then, we’ll get to the meat of the post, in which we’ll cover visual management itself. You’ll learn:

- the definition of visual management

- its history

- the workings of visual management, in more detail

- its main benefits

Last, but not least, we’ll cover the effective use of Visual Management tools. Let’s get started.

1. Brief History on Lean

Agile methodologies were a game-changer. There’s no denying that they played a crucial role in business operations and software development transformations in this almost complete first quarter of the 21st century.

But they’re called “methodologies”, plural, for a reason. Rather than being a single thing, agile is a collection of approaches, each with its own set of roles, rituals, and expectations about how work ought to be conducted in highly complex and uncertain projects.

One of the most influential “flavors” of agile is lean, which has its roots in the Toyota Production System, which dates back to the 1950s. The concept of Lean originated in the manufacturing industry, particularly with the Toyota Production System (TPS) developed by Toyota in the 20th century. It was influenced by the ideas of efficiency expert Frederick Winslow Taylor and statistician Walter Shewhart, among others. Lean principles emphasize the elimination of waste, continuous improvement, and respect for people, aiming to optimize processes and maximize value for customers. Over time, Lean methodologies have been adapted and applied to various industries beyond manufacturing, including healthcare, services, and software development, becoming a cornerstone of efficient organizational management.

2. Lean System Fundamentals

In a nutshell, the lean system is all about avoiding waste and increasing efficiency. Lean puts a big emphasis on continuous improvement, agility, avoiding any activities that don’t generate value, and ensuring you only build what’s needed and when it’s needed—in this regard, lean is related to the concept of just-in-time manufacturing.

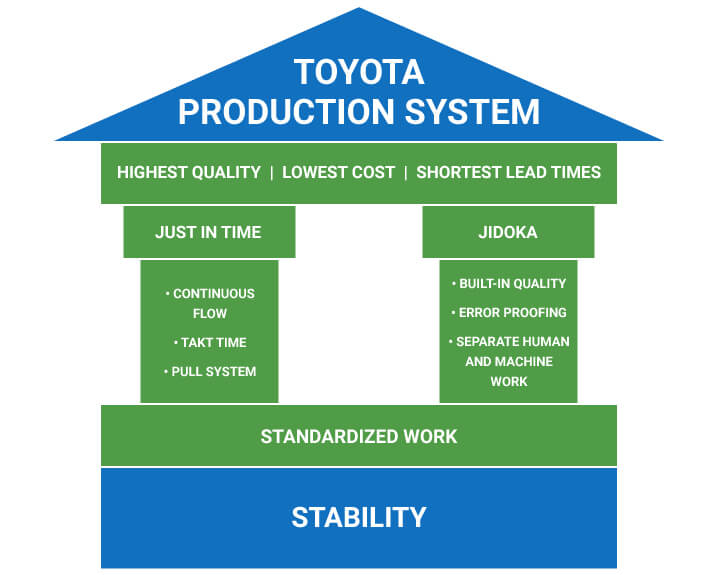

As you’ve seen earlier, the roots of the lean system are in the Toyota Production System (TPS). TPS was implemented and perfected in Toyota over several decades. Here’s how Wikipedia defines the main properties of TPS:

The main objectives of the TPS are to design out overburden (muri) and inconsistency (mura), and to eliminate waste (muda). The most significant effects on process value delivery are achieved by designing a process capable of delivering the required results smoothly; by designing out “mura” (inconsistency). It is also crucial to ensure that the process is as flexible as necessary without stress or “muri” (overburden) since this generates “muda” (waste).

Source: 5stoday.com

John F. Krafcik was responsible for the creation of the term “lean”, in the 1980s in the US.

When it comes to the benefits of lean, what are they? Here’s a non-exhaustive list, backed up by studies:

- decrease in labor costs

- inventory reduction

- production increase

- quality improvement

- reduce cycle times and lead times

3. Introduction To Visual Management

3.1 Visual Management: A Definition

In the context of lean, visual management is the practice of employing visual aids to make organizations more efficient, transparent, and collaborative. In more tactical terms, though, what are the benefits of this strategy?

The sooner something is made visible, the sooner it will be viewed—and, most importantly, acted upon. That’s, essentially, the sales pitch of visual management: let’s make problems, incidents, and data in general visible as soon as possible, in accessible and friendly formats. That way, teams inside your organization can make better-educated decisions.

3.2 Brief History of Visual Management

Visual indicators have been used to signal the status of work since probably the dawn of the industry. When we think of the modern incarnation of Visual Management, though, we can trace its roots to the 20th century, the lean system and, yes, you’ve guessed it: the Toyota Production System.

Source: uttana.com

Here’s a Forbes quote about the genesis of Visual Management:

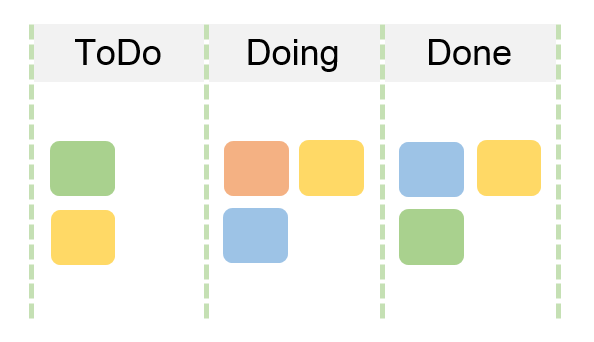

Toyota was the first company to take visual management into production in Japan in 1938, and its early philosophy of continuous improvement has since evolved into a global phenomenon known as “lean” management. It wouldn’t be for another 40 years that Western business leaders would learn of the Toyota Production System and its highly effective “kanban,” which is still used today to visually align production with demand in order to reduce waste.

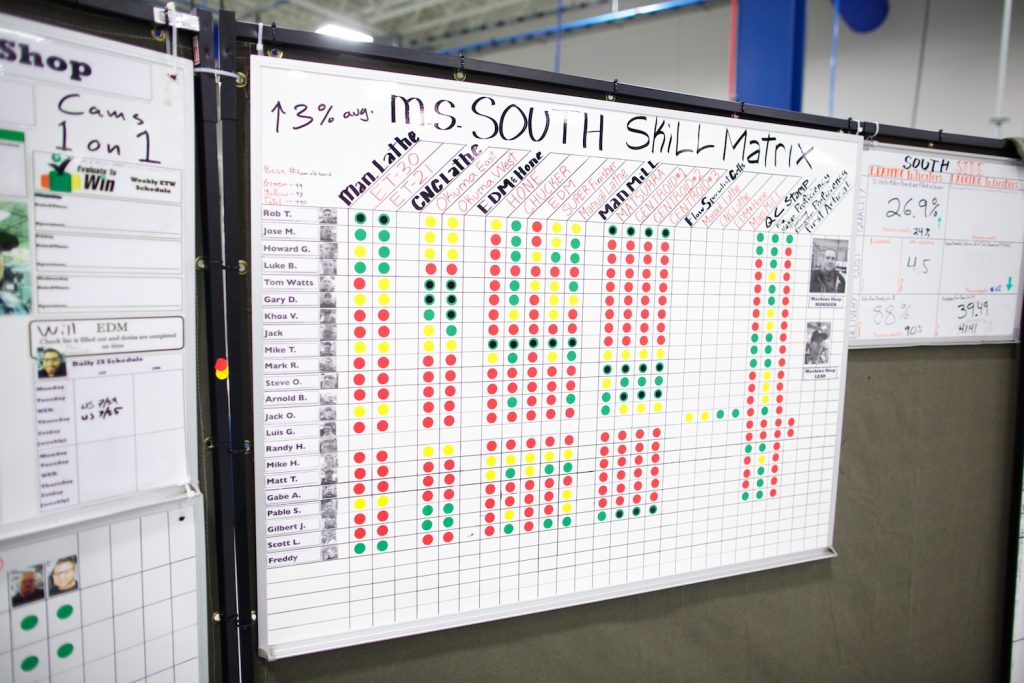

Visual Management’s whole deal is making data more visible. To accomplish data, it makes use of many resources and practices, such as kanban boards, whiteboards, Gemba walks, and more.

4. Visual Management Benefits – Why you Should care

Here’s a list of some of the main benefits of Visual Management.

4.1. Visual Management Facilitates the Understanding of Information

Visual management, when implemented correctly, not only makes information readability available but also broadcasts said information in an easy, digestible format, in which it can be consumed by all interested parties.

4.2. Visual Management Improves Communication

A logical consequence of the previous point. If visual management makes information available and easy to understand, it follows that the likelihood of miscommunications and misunderstandings goes down dramatically. The benefits of improved communication are hard to overstate, from fostering collaboration to increasing transparency.

4.3. Visual Management Increases Efficacy, Efficiency and Safety.

Another benefit of improved communication is the increase in efficacy—doing the right thing—and efficiency—doing it well, in a way that makes optimal usage of resources. if information is readily available, in a visual, reader-friendly format, information about standards and best practices can circulate easily, helping teams adhere to best practices and safety norms. As a result, mistakes are prevented and safety goes up.

4.4. Visual Management Results In Better Decision-Making

To make educated decisions, leadership has to have access to data. The data needs to be high quality and up to date, but also in a digestible format, and in the right amounts.

In other words: too little data is useless for decision-making. However, an excess of data (or data that is too complex) can be overwhelming and cause analysis paralysis.

Visual management solves that by serving data that is up-to-date, high quality, and easy to consume, thus enabling leadership to make informed decisions.

4.5. Visual Management Boosts Employee Morale

Last but not least, visual management can boost employee morale. It’s not hard to understand why: when having data about the teams and organization’s performance readily available, team members can see their impact and the value they generate. This can create a sense of purpose that boosts motivation and fosters a sense of belonging.

5. Using Visual Management Tools Effectively

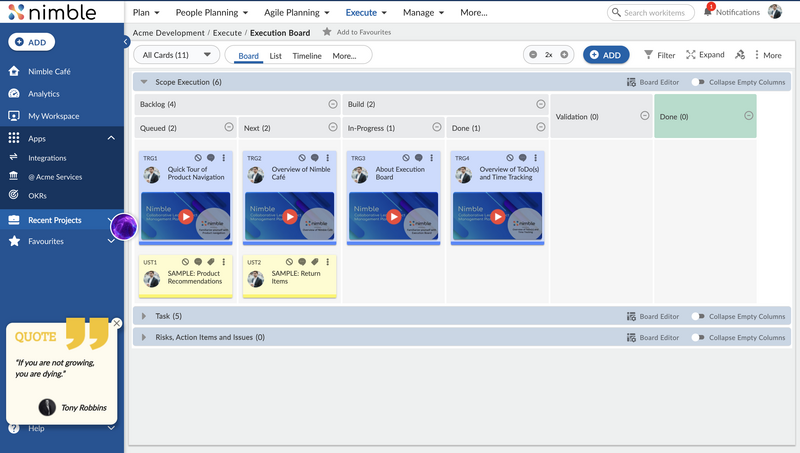

Last, but not least, we’ll offer some tips on how to use visual management tools effectively, including Nimble Work management as a visual management tool.

The first step to adopting visual management tools and using them effectively is to actually know the tools that exist. We’ve talked about Gantt charts and Kanban boards, but visual management tools assume a broad variety of shapes and sizes. Here are some more tools you must be aware of:

- Andon lights

- The 5S System

- Huddle boards

- Whiteboards and Post-it boards

- Nimble Work management

Visual Work Management with Nimble

Before rolling out your visual management, you’ll want to provide training for your team. This can take the form of workshops, information materials, training sessions, and other resources. Your team members must roll up their sleeves and start interacting and playing with the tools before the actual rollout. That way, they’ll be comfortable with the tools and processes from day one.

After understanding the offering of tools available picking the ones that make sense for you and training your team, the next step is starting! Understand the start won’t be as smooth as you’d wished, and that’s normal.

Make sure to have periodic evaluations of your visual management systems. Gather feedback on what’s working and what’s not. Adjust as needed and continue iterating on your process. Remember that a crucial pillar of lean is the concept of continuous improvement.

Ready to experience the power of visual management with Nimble? Sign up now for a free trial and revolutionize your team’s productivity! Start your journey towards efficient project management today.