Project management involves navigating complexities and overcoming challenges to ensure project success. Among the various tools available, the 5 Whys technique stands out for its simplicity and effectiveness in root cause analysis. By asking “why” five times, project managers can delve into the underlying causes of problems, fostering a culture of continuous improvement and proactive management.

The 5 Whys technique goes beyond surface-level solutions, encouraging teams to explore beyond the obvious. Each successive “why” peels back layers, revealing hidden connections and insights crucial for sustainable problem-solving. This depth of analysis is often underestimated but essential for effective project management.

Implementing the 5 Whys technique promotes a culture of inquiry and critical thinking within teams. It encourages collaborative problem-solving, as team members work together to understand root causes. This cultural shift, often overlooked, is vital for long-term success. Empowered teams are more engaged and invested in project outcomes.

The benefits of the 5 Whys extend beyond immediate problem resolution. By addressing root causes, project managers prevent future issues, leading to more predictable outcomes and efficient resource use. This proactive approach enhances communication and supports better risk management. The 5 Whys technique aligns with adaptive project management principles, driving meaningful and lasting improvements.

Source: citoolkit.com

1. Understanding the 5 Whys Technique

A. Origin and Evolution

The 5 Whys technique traces its origins back to Sakichi Toyoda, the founder of Toyota Industries, and it has been a cornerstone of the Toyota Production System since the 1930s. Initially developed to enhance manufacturing processes, its simplicity and effectiveness soon led to widespread adoption across various industries. The technique has since evolved, finding relevance in areas such as quality control, healthcare, and notably, project management.

B. Core Principles

At its core, the 5 Whys technique is built on the principle of iterative inquiry. By asking “why” multiple times—typically five, but sometimes more or fewer depending on the complexity of the issue—teams can move past surface-level symptoms to uncover the true root cause of a problem. The key principles include:

1. Simplicity: The technique requires no special tools or complex methodologies, making it accessible and easy to implement.

2. Focus: By concentrating on a single issue, the 5 Whys helps teams maintain clarity and avoid getting sidetracked.

3. Collaboration: Engaging the entire team in the inquiry process fosters diverse perspectives and more comprehensive solutions.

4. Documentation: Recording each step of the inquiry ensures that the reasoning behind decisions is transparent and can be revisited if needed.

2. Implementing 5 Whys in Project Management

When to Use 5 Whys

The 5 Whys technique is particularly useful in project management for addressing:

1. Recurring Problems: Issues that resurface periodically often indicate an underlying root cause that hasn’t been adequately addressed.

2. Complex Issues: Problems with multiple layers or contributing factors benefit from the structured inquiry that the 5 Whys provide.

3. Team Dynamics: Situations where team alignment and collaboration are crucial for problem resolution.

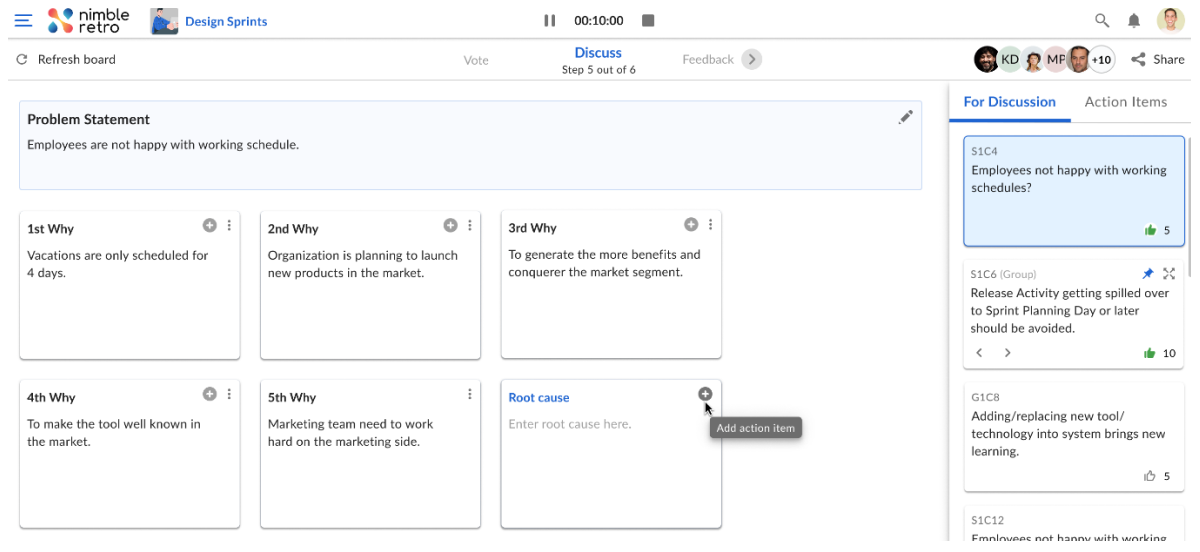

Step-by-Step Implementation Guide

1. Identify the Problem: Clearly define the issue at hand. Be specific to ensure the inquiry process is focused.

2. Assemble the Team: Include stakeholders and team members who are familiar with the problem and can contribute diverse insights.

3. Ask the First “Why”: Start with the initial problem statement and ask why it is occurring. Record the answer.

4. Ask Subsequent “Whys”: For each answer provided, ask why it is happening. Continue this process until you reach the root cause, typically after five iterations.

5. Develop Solutions: Once the root cause is identified, brainstorm and implement solutions to address it. Ensure the solutions are sustainable and prevent recurrence.

6. Review and Document: Document the process, findings, and implemented solutions. Review the outcomes to ensure the problem has been resolved.

Common Pitfalls and Solutions

1. Superficial Answers: Avoid settling for answers that only address symptoms. Push for deeper understanding.

2. Lack of Collaboration: Ensure all relevant team members are involved to gain a comprehensive view of the problem.

3. Inadequate Documentation: Thoroughly document each step to maintain transparency and facilitate future reviews.

4. Stopping Too Early: Sometimes, more than five iterations are necessary to uncover the true root cause. Be flexible and persistent.

By following these steps, project managers can effectively implement the 5 Whys technique to enhance problem-solving, improve team communication, and drive continuous improvement in their projects.

NimbleRetro – 5Whys

3. Benefits of 5 Whys for Project Managers

Enhanced Problem-Solving Capabilities

The 5 Whys technique empowers project managers to tackle problems at their core rather than addressing superficial symptoms. This methodical approach ensures comprehensive solutions, minimizing the chances of recurrence. The key benefits include:

1. In-depth Analysis: By delving deeper into issues, project managers can uncover hidden causes that might otherwise be overlooked.

2. Holistic Solutions: Addressing root causes leads to more robust and long-lasting solutions.

3. Prevention of Future Issues: Understanding the root cause helps prevent similar problems from arising in the future.

Improved Team Communication

The collaborative nature of the 5 Whys technique fosters open communication among team members. This enhanced communication translates into better project outcomes:

1. Shared Understanding: Team members gain a collective understanding of issues and their causes.

2. Enhanced Collaboration: Engaging the entire team in problem-solving promotes diverse perspectives and solutions.

3. Increased Transparency: Documenting each step of the inquiry process ensures that all team members are on the same page.

Efficient Resource Allocation

By identifying the root causes of issues, project managers can allocate resources more efficiently:

1. Targeted Interventions: Resources can be directed towards addressing the root cause rather than merely mitigating symptoms.

2. Cost Savings: Preventing issues from recurring reduces the need for repeated resource allocation.

3. Optimized Effort: Teams can focus their efforts on solutions that provide the most significant impact.

Proactive Risk Management

The 5 Whys technique supports proactive risk management by identifying potential problems before they escalate:

1. Early Detection: Uncovering root causes early in the project lifecycle helps prevent larger issues.

2. Risk Mitigation: Addressing root causes reduces the likelihood of risks materializing.

3. Continuous Improvement: The iterative nature of the 5 Whys promotes ongoing risk assessment and management.

4. 5 Whys vs. Other Root Cause Analysis Methods

Comparison of Techniques

Several root cause analysis methods are available, each with its strengths and weaknesses. Comparing these techniques can help project managers choose the most suitable approach:

1. Fishbone Diagram (Ishikawa): Visual tool that helps categorize potential causes but can become complex with numerous factors.

2. Failure Mode and Effects Analysis (FMEA): Systematic approach for identifying and prioritizing potential failure modes, useful for complex projects but time-consuming.

3. Fault Tree Analysis (FTA): Graphical representation of fault paths, effective for technical issues but requires specialized knowledge.

Choosing the Right Method

Selecting the appropriate root cause analysis method depends on various factors:

1. Complexity of the Problem: Simpler issues might benefit from the 5 Whys, while more complex problems may require FMEA or FTA.

2. Available Resources: The 5 Whys technique is resource-efficient, requiring minimal training and tools.

3. Team Expertise: Consider the team’s familiarity with different methods and their ability to implement them effectively.

4. Project Scope: Larger projects with higher stakes might benefit from more detailed analyses like FMEA.

5. Advanced Applications of 5 Whys

Integration with Other Project Management Tools

The 5 Whys technique can be seamlessly integrated with other project management tools to enhance its effectiveness:

1. Kanban Boards: Use the 5 Whys to investigate bottlenecks and improve workflow efficiency.

2. Gantt Charts: Apply the technique to identify and address delays in the project timeline.

3. Risk Registers: Incorporate 5 Whys analysis to uncover the root causes of identified risks and develop mitigation strategies.

The “5 Whys Plus” Approach

Expanding on the traditional 5 Whys technique, the “5 Whys Plus” approach includes additional steps to ensure comprehensive solutions:

1. Validation: Verify that the identified root cause is accurate and that the proposed solutions are effective.

2. Implementation: Develop and execute an action plan to address the root cause.

3. Review: Continuously monitor the implemented solutions to ensure they are working as intended.

Quantitative 5 Whys Analysis

While the 5 Whys technique is typically qualitative, it can be enhanced with quantitative data to provide more robust insights:

1. Data Collection: Gather relevant data to support each “why” and provide evidence for the identified causes.

2. Statistical Analysis: Use statistical methods to analyze the data and validate the root cause.

3. Metrics: Develop metrics to measure the effectiveness of the implemented solutions and track improvements over time.

6. Conclusion: Importance of 5 Whys in Project Management

The 5 Whys technique is a powerful tool for project managers, offering a simple yet effective method for root cause analysis. By fostering a culture of inquiry, enhancing problem-solving capabilities, and promoting continuous improvement, the 5 Whys technique helps project managers navigate challenges, optimize resources, and deliver successful projects consistently. Integrating this technique with other project management tools and methodologies can further amplify its benefits, making it an indispensable part of a project manager’s toolkit.

7. Additional Resources: NimbleWork’s Retrospective Tool for 5 Whys Implementation

To support project managers in implementing the 5 Whys technique, NimbleRetro offers a comprehensive retrospective tool. This tool facilitates the 5 Whys process, enabling teams to document each step, collaborate effectively, and track the outcomes of their root cause analysis efforts. By leveraging Nimble’s retrospective tool, project managers can enhance their problem-solving capabilities and drive continuous improvement in their projects.